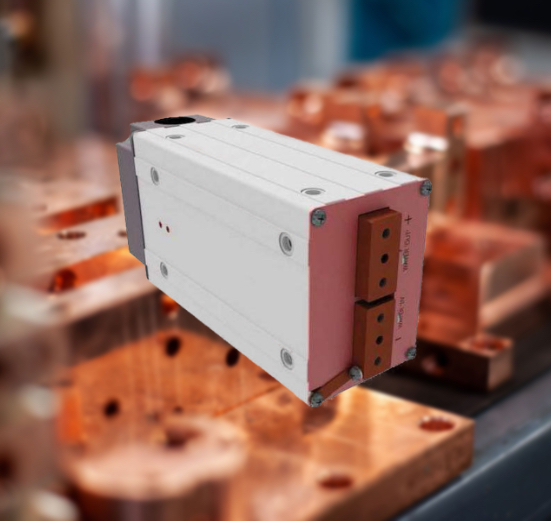

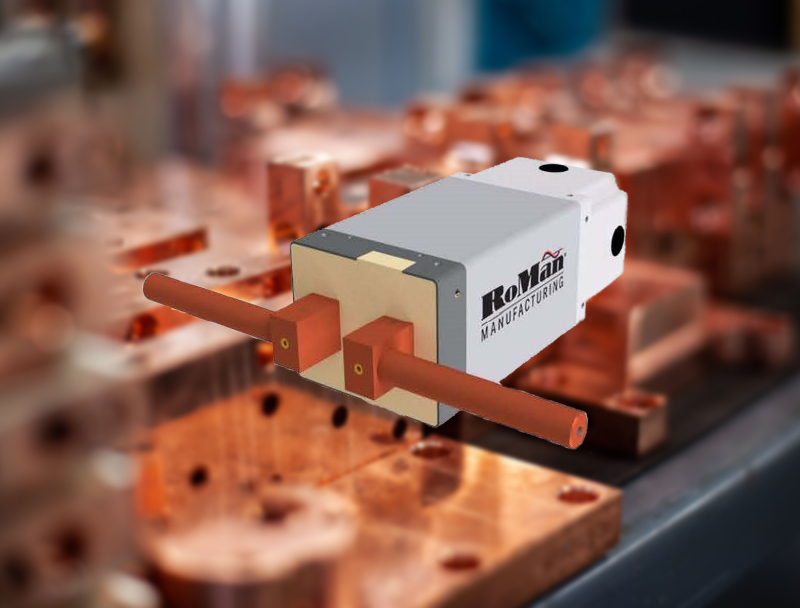

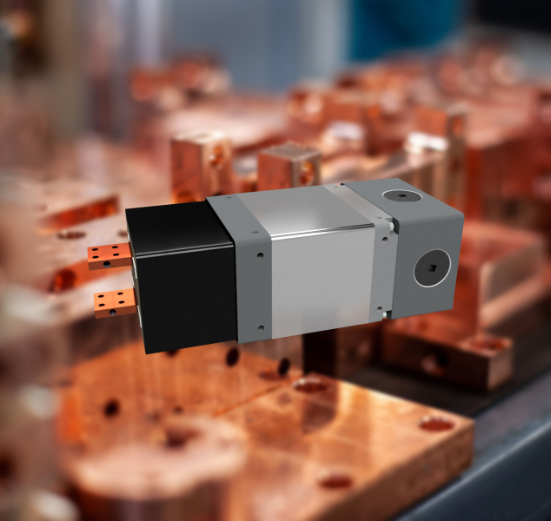

Glass

RoMan water-cooled transformers are optimized for the melting, boosting, and forming of glass. They are smaller in size than conventional air-cooled and oil-cooled units, so they can be installed (closely coupled) next to the heat source. Close coupling reduces energy consumption, component costs and space needs. It also eliminates harmonics and heat dissipation, while increasing the system’s power factor. RoMan offers multiple design options and integration with IGBT controls, or any other type of power control.